|

ASROC HANDLING & LOADING

By Dave ("Boomer") Hood, GMT2, USS McKean (DD 784)

Dedicated to the memory of Thomas Best. A fellow ASROCATEER

RECEIVING AND INSPECTING

THE WEAPON RECEIVING AND INSPECTING

THE WEAPON

When an ASROC weapon is received by a firing ship

(Destroyer, Frigate, Cruiser) it will arrive in a shipping container, commonly

called a coffin. Once the weapon is on deck inspect the container for proper

stenciling and any visual damage. (Dents, missing parts, corrosion.)

Relieve pressure in the container by depressing the bleed off valve and

then remove the upper half of the container.

INSPECT THE WEAPON

The color of the weapon’s warhead indicated what type of weapon it was.

Blue – Inert. A training shape used to familiarize

the handling team with loading procedures.

Orange - Exercise. No explosive. The warhead is filled with lead shot and

sea dye. It was designed to

be recoverable. It may contain

recording devices so that technicians could analyze the weapons track and

attack. The rocket motor is

certainly real and needs to be treated with all due respect and safety

precautions.

Green with yellow bands. A war shot torpedo. The

explosive warhead may contain either H6 or PBXN explosive.

The Marine Rifle Squad that accompanies it during its transit and

transfer can readily identify a nuclear depth charge ASROC.

Are there any

visual defects? Are all components installed? Fins. Logbook. Umbilical cable.

P1 shorting cab plug. Nose cap. Sea dye marker in the nose cap. Thrust

neutralizer. Any standing water or moisture in the bottom of the container. Are there any

visual defects? Are all components installed? Fins. Logbook. Umbilical cable.

P1 shorting cab plug. Nose cap. Sea dye marker in the nose cap. Thrust

neutralizer. Any standing water or moisture in the bottom of the container.

Once it passes a visual inspection, the weapon is then

physically inspected. Are there any cracks? Do the components mate up? Are the

explosive blocks used to separate the components in-flight installed correctly?

Of

all the weapons I received, only one had a defect. An exercise torpedo ASROC

arrived with a depth charge nose cone on. The torpedo nose cone is slightly

smaller. We loaded the weapon

anyway and, the next workday returned the nuclear nose cone to the USS DIXIE

AD14 where we swapped for the correct part.

ASAFETY PRECAUTION!

Establish H.E.R.O. (Hazards of Electronic Radiation to Ordnance) Safety.

Establish Shipboard Weapons Security.

MOVING

THE WEAPON MOVING

THE WEAPON

If the weapon is satisfactory and you have signed custody

for it, now you must put it somewhere. Because

the weapon weighs 1500 pounds, special equipment is required to move it on top

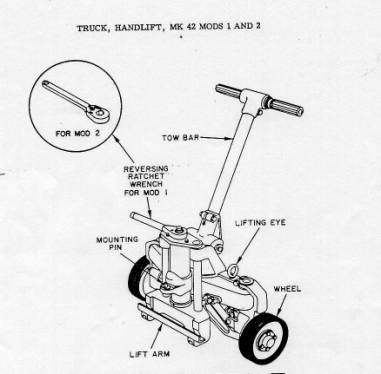

of a ship’s deck. See at left, Figure 3 -the

MK 42 Handlift Truck.

From their

storage space, retrieve your MK 42 Hand-lift trucks (quantity, pair. Unit of

issue, 2 each.) These look like two-wheeled floor jacks with a ½” ratchet on

top. Maneuver a Hand-lift truck onto each end of the lower portion

of the shipping container (the half with that contains the weapon) and attach to

the proper recess. Using the ratchet, take up the slack. Stop when you meet

resistance. Then, with one person on each truck, synchronize your lifting until

the container is fully off the deck. The

container can then be rolled on the deck.

LOADING INTO A MAGAZINE

Should you wish to transfer your weapon to a magazine for

storage, remove the magazine door ramps from their storage brackets and place

one on the inside of the door and one on the outside of the door.

You may then roll your container into the magazine.

ASAFETY

PRECAUTION! The smoking lamp is OFF while handling weapons.

Inside the magazine, cigarettes, pipes, cigars, matches, lighters, keys

and tools capable of producing a spark are prohibited.

Station someone OUTSIDE of the door to ensure that handling personnel do

not bring these items inside the magazine. (Chewing tobacco or snuff is

authorized provided the users do not need to spit.)

Place the container under the Overhead Magazine Loader

Crane. Move the Overhead crane over the weapon and attach to the ASROC Missile

Rail Slots located on the Missile Airframe Upper Clamshell.

Disconnect the ASROC Missile Shipping Container Retaining Bands that

secure the missile to the container. Using

synchronized operation of the Hand-lift truck elevation/depression ratchets,

DEPRESS (lower) the container until the weight load has been transferred to the

Overhead Magazine Loader Crane.

ASAFETY

PRECAUTION! Prior to attaching any ASROC missile to the Overhead Magazine

Loader Crane, inspect the Overhead Magazine Loader Crane for current Weight Test

Inspection. Inspect for rust,

damage, or any missing parts.

Using the pulley system, raise the ASROC weapon high

enough to clear the chocks and move the crane fore & aft and laterally as

necessary to place the weapon over the desired storage chocks.

The now-empty container may be removed to any desired location.

Using the pulley system, lower the weapon onto the bottom

portion of the storage chocks until the weight of the weapon is transferred onto

the chocks. Release the Overhead Magazine Loader Crane from the ASROC Missile

Rail Slots and move the Overhead Magazine Loader Crane to its normal storage

position. Attach the upper portion of the storage chocks and install the

stainless steel bolts, washers and nuts. Tighten with brass or aluminum wrenches

only.

ASAFETY

PRECAUTION! The ASROC missile is to be stowed with its

motor end facing the ASROC Magazine Bulkhead Blowout Port.

(On a FRAM these ports are on the fore end of the bulkhead. Therefore,

the weapon should be facing aft in the magazine.) ASAFETY

PRECAUTION! The ASROC missile is to be stowed with its

motor end facing the ASROC Magazine Bulkhead Blowout Port.

(On a FRAM these ports are on the fore end of the bulkhead. Therefore,

the weapon should be facing aft in the magazine.)

Once the weapon is secured in the chocks remove the

thrust neutralizer and place it in storage. Mounted in the magazine bulkhead are

Blowout ports. If a weapon should have an accidental motor ignition while in the

magazine, the blast will be blown out the Blowout port and vented OUT of the

magazine. (See Figure 4 at left - Blowout ports in the

ASROC bulkhead (USS McKEAN DD-784)

ASAFETY

PRECAUTION! In the event of an accidental motor ignition in the ASROC

magazine, do not stand in front of the Blowout ports until motor ignition has

ceased.

LOADING AN ASROC MISSILE INTO THE LAUNCHER

Select which type of payload you wish to load into your MK 112 ASROC launcher.

Select that cell you wish to load your payload into.

ASAFETY

PRECAUTION! Ensure that all weapons handling is done in an approved

weapons handling area. Ensure the Bravo flag is flying.

Ensure HERO (Hazards of Electronic Radiation to Ordinance) standards are meet.

Ensure appropriate security precautions have been meet.

For FRAM 1 ships:

Remove the canvas cover off of the ASROC Loader Crane.

Inspect the sight glass in the ASROC Loader Crane Hydraulic Pump Sump for

proper hydraulic fluid level. (The sump is located in the Oil King Shack. It’s

not uncommon to find that the Oil King has accidentally broken the sight glass.)

Open the hatch to the ASROC Loader Crane Rail Storage

Locker. (The locker is that metal container 4’x4’x15’ on the ASROC deck

next to the motor whaleboat. It

will contain the loader rail, lockers for the MK13 RTDC thermal batteries, cans

of PD-680 solvent, bails of rags and is a handy place to store 10-speed bicycles

and SCUBA gear – all of which must be hidden prior to an N.T.P.I.)

Manually rotate the ASROC Deck Loader so that its aft end faces Rail

Storage.

Slide the loader crane out on its rollers and mate it with the ASROC Deck

Loader. Disengage the Loader Rail from the overhead track in Rail Storage.

Hook up the QD hydraulic hoses from the ASROC Deck Loader to the ASROC

Loader Rail rammer.

Activate the ASROC Deck Loader hydraulic pump.

Manually rotate the ASROC Deck Loader so that it is now athwartships (along

the beam and not along the keel).

Using hydraulic power, raise the ASROC Deck Loader.

Using the MK 42 hand-lift trucks, maneuver a weapon (in the lower half of a

shipping container) UNDER the ASROC Deck Loader.

ASAFETY

PRECAUTION! Ensure the warhead portion of the ASROC missile goes

underneath the FRONT portion of the ASROC Loader Crane and the rocket motor end

(with the installed Thrust Neutralizer installed in the rocket motor and

properly torqued to 100 ft/lbs. +/- 10 ft/lbs.) under the ASROC Loader Crane

Rammer.

Remove the blast cover (“Elephant Skin”) from the aft end of the ASROC

cell to be loaded.

From the right-hand panel of the MK 199 ASROC Launcher Captain’s Control

Panel select the cell to be loaded. This will open the front doors, extend the

rail and release the snubbers.

Lower the ASROC Deck Loader until

it is just above the ASROC missile. Lower the ASROC Deck Loader until

it is just above the ASROC missile.

Using the Elevation/Depression ratchet on the MK 42 hand-lift trucks, RAISE

the ASROC shipping container until the weapon’s T-rails (located on the

missile’s Airframe Separation Assembly Section) mates with the cutout recesses

in the ASROC Loader Rail.

Using the rammer hand-crank, move the weapon forward so the t-rails clear

the rail cutouts.

Using the Elevation/Depression ratchet on the MK 42 hand-lift trucks, LOWER

the ASROC shipping container until it is just off of the ground.

Using the ASROC Deck Loaders Hydraulic elevation control handle, raise the

weapon high enough so that the now empty shipping container can be taken out of

the loading area.

Using the ASROC launcher’s train air drive motor, rotate the launcher to

the proper degree for the desired cell to be loaded.

Crawl

into the ASROC launcher carriage and, using a slotted screwdriver on the proper

Guide Drive Pin Solenoid, pop the solenoid to engage the Guide Drive Pin with

the Elevation Torque Tube. See Figure 6 - Guide

select solenoid found inside the MK 7 Carriage (USS ORLECK DD-886). Crawl

into the ASROC launcher carriage and, using a slotted screwdriver on the proper

Guide Drive Pin Solenoid, pop the solenoid to engage the Guide Drive Pin with

the Elevation Torque Tube. See Figure 6 - Guide

select solenoid found inside the MK 7 Carriage (USS ORLECK DD-886).

Using the ASROC launcher’s elevation air drive motor, elevate the

cell to be loaded to the proper elevation angle (measured in MINUTES) so that

the Loader Rail can be mated with the cell’s Rail Supports.

A Helpful hint.

Hopefully, you will have all of this loading data written down in a logbook. Do

not lose that logbook. It will simplify your life.

On the side of the Loader Crane Pivot Head is a big red handle. That allows

the Pivot Head to pivot. Pull the handle.

Using the Elevation Air Drive Motor, elevate the desired cell to the proper

angle (measured in MINUTES) as recorded in your Loading Data Logbook.

Verify the proper relationship between the selected cell to be loaded and

the ASROC Loader Rail by sliding the T-RAIL tool along the slots in the

Launching Rail and the Loader Rail. The T-RAIL tool should slide along freely ON

BOTH SIDES of the Loader Rail.

A

Safety Precaution! If the T-RAIL tool does not slide freely DO NOT ram

the missile from the Loader Rail into the cell. It will bind on the track.

Damage to both the ASROC weapon and the Mk7, Mod 1 ASROC Launcher Guide may

result. Make minor adjustments to either the elevation or train angles (or to

both) and then check the angle relationship with the T-RAIL too.

Use the ASROC Deck Loader’s Hydraulic control to Power Ram the missile

into the cell. Power ramming will cease when the missile still has approximately

12” to go.

Using the Restraining Latch Release Tool, manually pull down so the

RESTRAINING LATCH can receive the missile.

Using

the hand crank on the end of the ASROC Deck Loader Rail, ram the missile the

rest of the way into the cell. The sailor holding down on the Restraining Latch

Release Tool will feel the weapon seat itself into the Restraining Latch. He can

now release tension from the tool. Using

the hand crank on the end of the ASROC Deck Loader Rail, ram the missile the

rest of the way into the cell. The sailor holding down on the Restraining Latch

Release Tool will feel the weapon seat itself into the Restraining Latch. He can

now release tension from the tool.

Use the Elevation Air Drive Motor to depress the selected cell to the

proper angle (measured in MINUTES) so that the ASROC Loader Rail can be detached

from the cell’s Rail Supports.

From the aft end of the cell, attach the firing umbilical cable to the

missile and to the cable terminal. Tighten with a cable spanner. Re-install the

blast cover to the aft end of the cell. See Figure 7-at

left. Aft end of MK 112 ASROC Launcher showing "Elephant skin" blast

covers. Note that cell thermometers are missing from some of the cells. (USS

ORLECK DD –886)

If no other ASROC weapons are to be loaded, secure the ASROC Loader Rail and

Deck Loader. If more ASROC weapons are to be loaded into the MK 112 ASROC

Launcher, repeat the above steps for each cell to be loaded.

|